Expanding the life cycle: with spare parts as good as new

Sustainability is one of the values that the Bizerba brand stands for. The best return on investment protection we can offer clients for our solutions. Among other things, we secure it with

- High-grade materials that we process in our solutions,

- Warranty periods that extend far into the future, and

- A spare-parts logistics that consistently includes more than 20,000 original Bizerba spare parts. Including electronic components.

The circular economy ensures the long-term availability of these electronic spare parts. This is the process:

Buying back old devices

If a company invests in a new solution from our range of products, we are happy to offer the company a realistic buy-back offer for the old unit or system.

In the next step we return it to the refurbishing process:

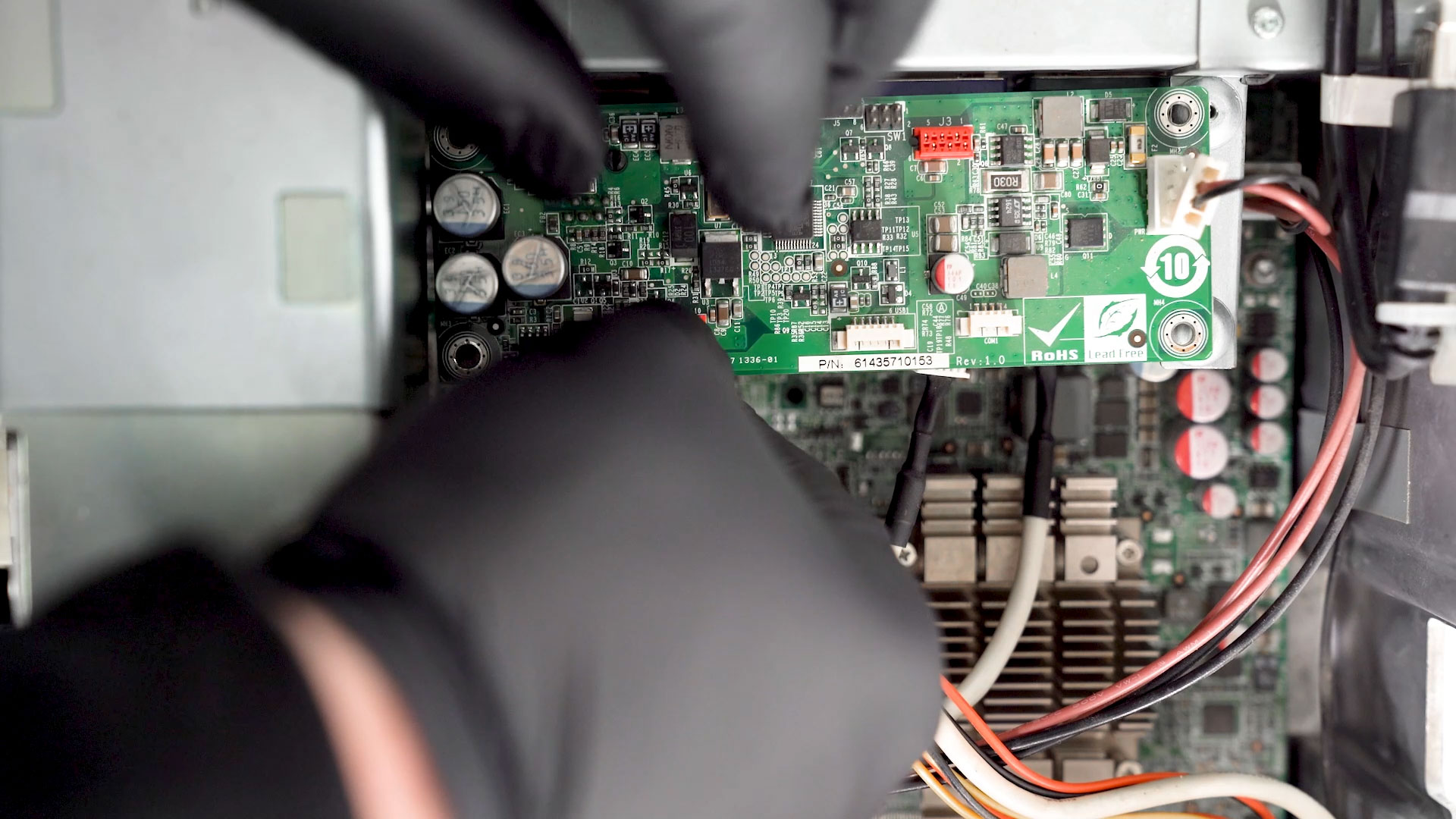

- Valuable e-components, such as printed circuit boards, CPUs, applicators, printing mechanisms or entire sub-assemblies, are collected,

- Metals sorted by type returned to the material cycle and recycled

- installed batteries and unusable electric scrap professionally disposed of.

Refurbishing made by Bizerba

We refurbish all useable electronic components in-house. Before any of them return as a good-as-new spare part into the supply chain, Bizerba specialists

- inspect,

- clean,

- process, and

- test each one of them.

The part is subjected to the same quality control process that we apply to any new part. And our technicians and repair specialists do even more:

Printed circuit boards always leave the workshop in state-of-the-art condition. They are absolutely equivalent to those that just left production five minutes earlier. The only difference:

Refurbished spare parts last longer, are more readily available & financially attractive.

If the client returns the defective part to us for repair, we will supply the replacement part as good as new at a lower price.

Major added value: autonomy

Not only does refurbishing conserve valuable resources – the strategy is also the best way to prevent potential supplier crises. Given the globally disrupted supply chains, almost every industry is facing enormous challenges. Long, at times uncertain, lead times are the consequence for the clients.

Refurbishing disengages us from a situation of this kind for the most part. It minimizes the risk of losing the business's ability to act. Not only for us, but for our clients as well. By refurbishing electronic components, we are able to counteract the shortage of components in many areas while reliably delivering solutions to our clients.

Autonomy also means: you as an entrepreneur decide long-term whether you

- extend the life cycle of your solution cost-effectively with refurbished e-components, or

- invest cost-efficiently in fully refurbished solutions in original Bizerba quality. We also offer this resource-friendly alternative under the RefurBiz label.