- 2005 founded

- 65 Employees

- 3.37 mio. pouches inspected per year

Wanted: food safety solution for end-of-line

The Baby Food Company had a robust Food Safety Management System in place, equipped with metal detection systems to eliminate packages containing foreign bodies. These might originate from any production stage—from harvesting to processing—and accordingly consist of various materials. Despite those thorough precautions, there was still a possibility that compromised packs might bypass upstream systems and checks.

New production line with new safety concept

And so, as they planned a new production line for fruit pulp in pouches, The Baby Food Company sought to incorporate an even more thorough and comprehensive end-of-line check. This system needed to be highly sensitive to a huge variety of contaminants—metals, glass, plastic, bone fragments, and stones—and capable of automatically ejecting compromised packages. The detection sensitivity had to be very high to achieve this. The X-ray machine had to be easy to clean and user-friendly for operators. Moreover, the solution required a compact design to fit the limited space available at the end of the line.

Found: a refurbished high-end X-ray system

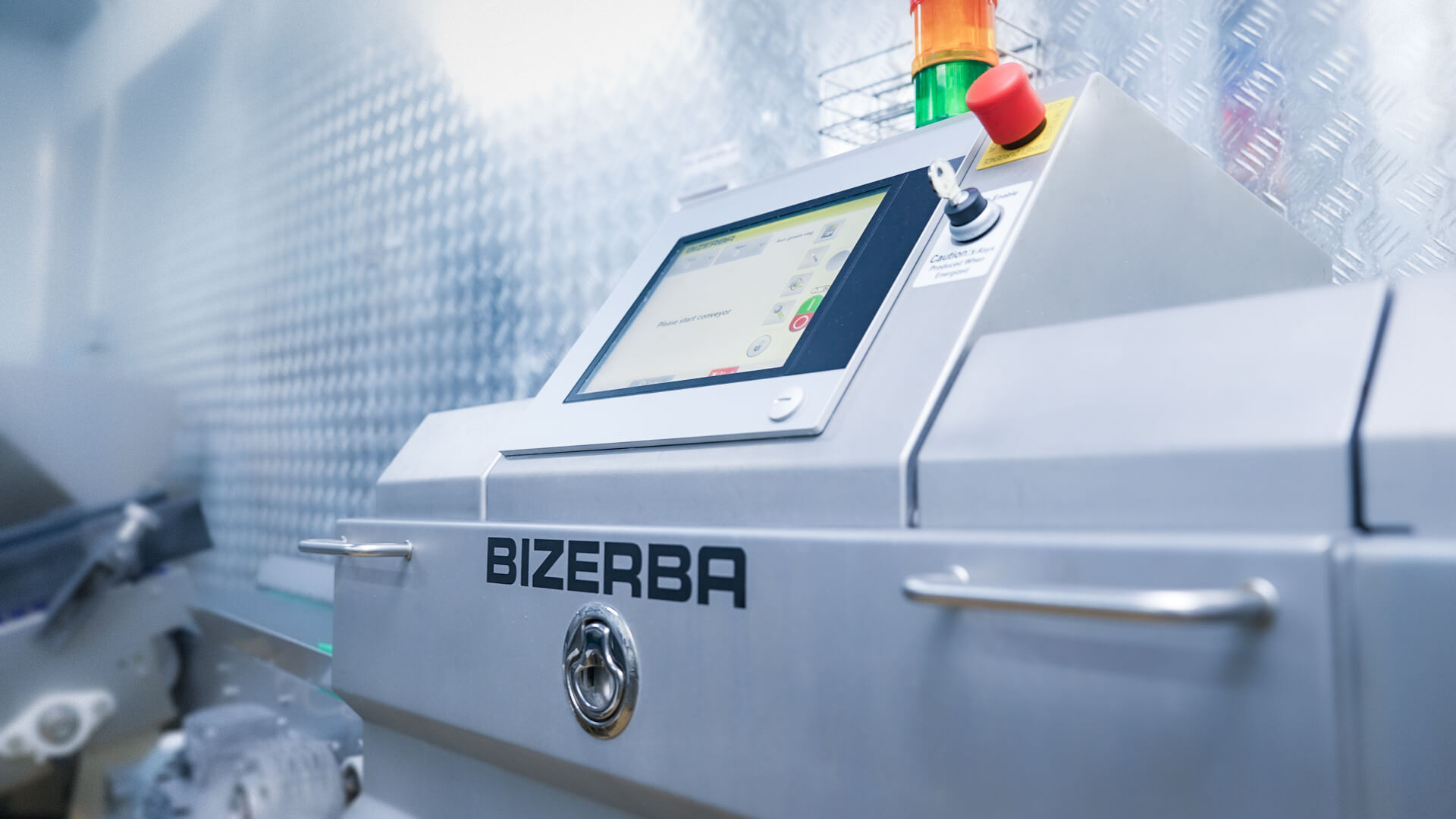

For a mid sized business as The Baby Food Company, a high-end X-ray inspection system is quite an investment. Doing their market research for an affordable solution, the company discovered Bizerba’s selection of refurbished second-hand hardware. On offer there: an X-ray Inspection System XRE-D 200/120—just what they were looking for.

Pre-loved system is affordable for smaller businesses

X-ray detection boasts a higher sensitivity for typical metallic objects and can detect certain non-metallic objects depending on their density. The XRE-D’s high detection sensitivity, compact footprint, and, not least, its affordable price convinced The Baby Food Company’s founder and technical director, Rozi Andrew: 'As a small business, we decided to opt for a pre-loved model. The pricing structure for new X-ray machines often makes them unaffordable for smaller businesses, so buying a pre-loved or demo unit made this technology accessible.' In August 2023, Bizerba seamlessly integrated the system into the new production line, networked processes, and data management.

Detects contaminations and weight deviations

The X-ray detection system reliably identifies contaminants and automatically ejects compromised packages from the production line. This greatly reduces the risk of contaminated goods reaching the market and triggering product recalls. Besides detecting metallic and non-metallic foreign objects, the system also identifies missing, defective, or misshapen products, as well as items that are overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes.

More data for optimized food safety

The new X-ray detector plays a vital role not only in securing food safety pack per pack. It also delivers valuable data that improves product safety management at The Baby Food Company’s. Rozi Andrew: ”Product safety is paramount to our business, so equipment such as metal or X-ray detectors plays a vital role in managing and securing product safety.” Regarding future technology investments, Andrew says: ”We were new to Bizerba. But if we need new equipment again, we will definitely check in with what Bizerba has to offer.”

Let’s count