Why Tray Sealers are Essential in Food Production

Food packaging demands a high level of reliability, and tray sealers are designed to meet these challenges. Whether packaging meat, fish, dairy, or produce, tray sealers help ensure that each product is sealed in a way that preserves freshness. MAP and VSP systems replace the air inside the packaging with protective gases or remove it entirely, creating a secure environment that slows down spoilage and reduces bacterial growth.

Extended Shelf Life: With MAP, foods like meats and vegetables can stay fresh longer by using gases like nitrogen to keep the food intact and appealing to customers. This method is critical in extending shelf life while reducing food waste.

Enhanced Freshness: VSP seals products tightly, locking in freshness and keeping products in peak condition. This type of packaging is ideal for seafood and delicate meats that require airtight packaging to preserve quality.

High-Efficiency Packaging for Fast-Paced Environments

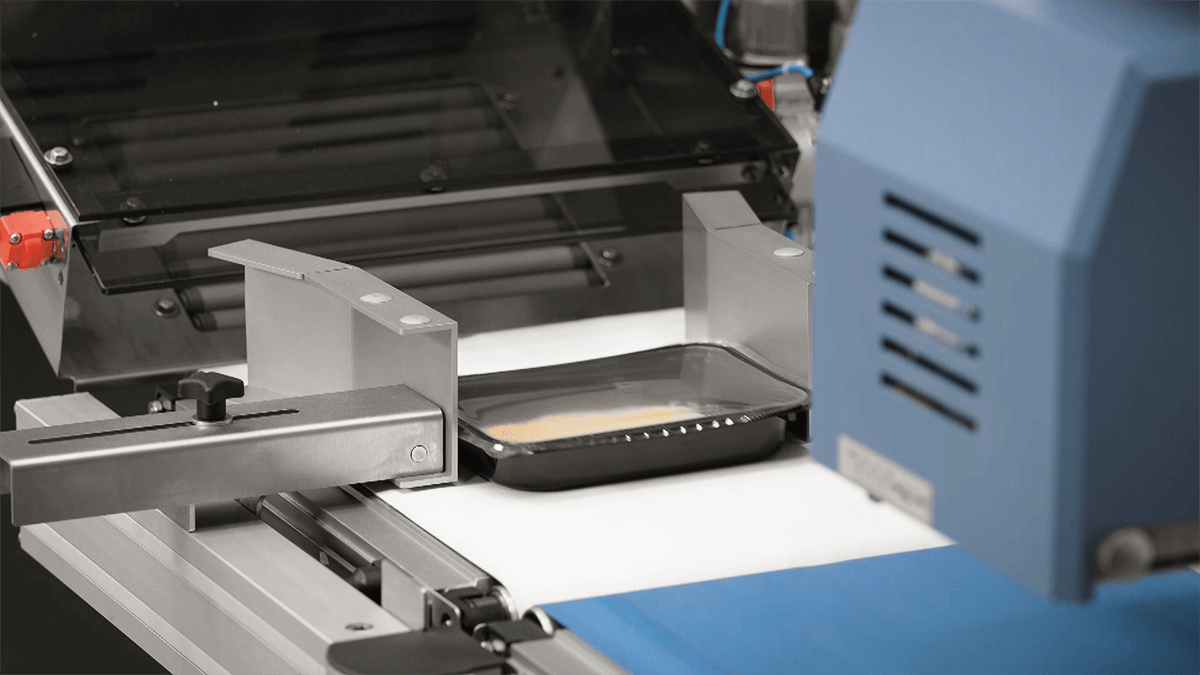

In high-volume food production, speed and efficiency are crucial. Tray sealers are designed to handle large quantities of food packaging without slowing down the production process. These machines offer high-speed operations, meaning they can package numerous trays in a short time, helping producers meet demand efficiently.

Flexible Handling: Modern tray sealing machines can handle different tray sizes and shapes, providing flexibility for food producers who need to switch between products quickly. This capability is especially important for businesses that package a variety of goods, from small snacks to large portions of meat or vegetables.

Automation for Efficiency: Automation in tray sealing technology helps reduce the need for manual labor, speeding up processes and improving the overall consistency of seals. Automated systems reduce the risk of errors, ensuring that every package is securely sealed and ready for shipment or sale.

Built for Durability and Hygiene

In the food industry, where hygiene and cleanliness are critical, tray sealers are built to withstand tough environments. Many models feature stainless steel construction, ensuring that they remain durable and easy to clean. Stainless steel prevents corrosion and allows for frequent washdowns, which are essential in maintaining food safety standards.

Easy Maintenance: Stainless steel tray sealers are not only durable but also simple to maintain. Their surfaces can be cleaned quickly, ensuring that food producers can meet strict hygiene standards with minimal downtime.

Consistent Sealing for Food Safety: The reliability of tray sealers ensures that every tray is securely sealed, preventing contamination or spoilage. By ensuring an airtight seal, tray sealers help maintain product safety throughout the entire supply chain.

Applications Across the Food Industry

Tray sealers are versatile machines that serve many segments of the food industry. From meat processors to vegetable packers, these machines provide a consistent and reliable way to package food. They are used across different sectors to package both fresh and processed goods, ensuring that consumers receive high-quality products.

Dairy and Meat Packaging: The dairy and meat sectors benefit immensely from tray sealers, especially when used with MAP technology. These systems help keep products fresh and reduce spoilage, a critical factor in these highly perishable goods.

Ready-to-Eat Meals: Tray sealing is also widely used in packaging ready-to-eat meals, which are sealed to maintain freshness until the moment of consumption. This packaging method is critical for maintaining the taste, texture, and nutritional value of pre-prepared meals.

In summary, tray sealers are indispensable for food producers looking to preserve product quality, extend shelf life, and ensure safety. With advanced packaging technologies like MAP and VSP, food producers can rely on tray sealers to maintain freshness and prevent spoilage. Their durability, flexibility, and high-speed operation make them essential tools for any food production facility.

By investing in high-quality tray sealers, food businesses can optimize their operations, reduce waste, and deliver products that meet the highest standards of safety and freshness.