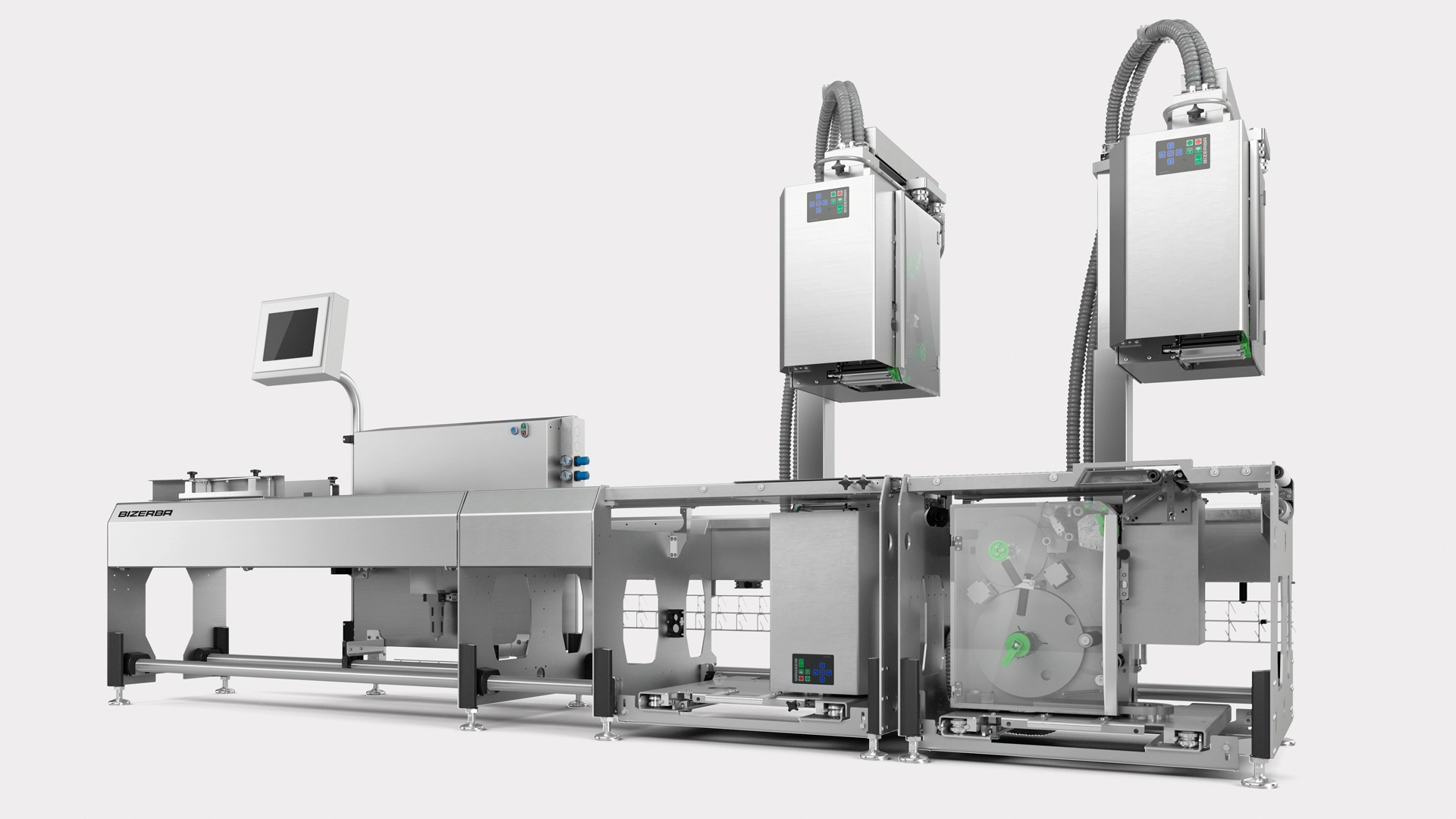

Fully automatic labeler for goods labeling GLM-Ievo with C-Wrap applicator

With the GLM-Ievo C-Wrap, labels can be applied over three sides. Depending on the requirements, the label can be placed on the side or in the middle. By using C-Wrap labels, the product can be presented optimally, as the large label offers plenty of space for advertising messages. In alternating operation with two labelers, the label roll can be changed without stopping the system. This reduces setup time and enables optimal pack throughput. By integrating an additional top/bottom labeler, the system can also be used for classic top/bottom price labeling. This means that the system offers a high degree of flexibility. Thanks to its modular design, it can be optimally configured for the products and performance requirements in the food sector. Thanks to the modular system and high throughput, there are no limits to current and future requirements in the industrial food sector. In addition to its flexibility, this award system impresses with its robustness and easy-to-clean design. Its intelligent visual quality control (optional) and automated activation of the process data via the Plug-In® label function make operation easier and reduce errors in the packaging process.

Highlights

Product images and technical information may differ and may not be available in your country.

Details & Options

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again