Profitable, productive work is the aim of every company that thinks in economic terms. Machinery and plants that are efficiently utilised have a direct impact on production. However, other factors also have a direct impact on cost-effectiveness: machinery and plants also cause costs that are not limited to the acquisition. The notion of life cycle costs takes this into account: many investments turn out to be cost traps despite low initial procurement costs.

The costs of operating a product exceed the investment costs many times over

To act cost-effectively over a prolonged period of time, all cost factors must be borne in mind when planning investments. In such cases, the whole life cycle of a product is considered and the procurement costs often fade into the background relative to operating costs: "various investigations have shown that the costs of operating a product exceed the investment costs several times over. This is due to the long service life of the products where the costs for operating and maintaining the plants are recurring. The LCC value is therefore of strategic importance within procurement for the production team, however it is still underused as a tool in day-to-day industrial affairs for targeted investment planning", states Gerd Kammerer, Director of Product Line Management at Bizerba.

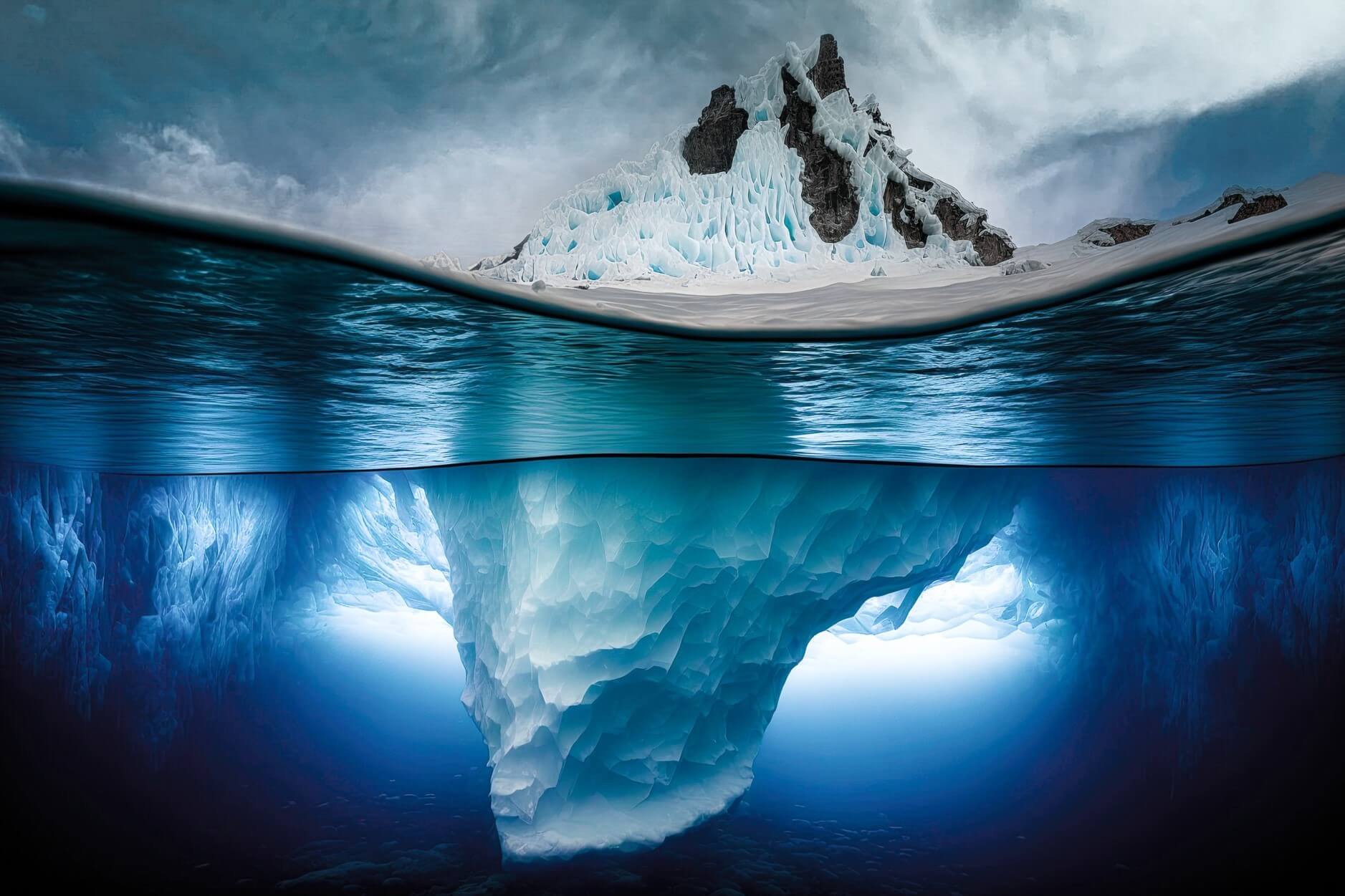

What lies below the surface

Just like an iceberg, many costs that arise during the service life of a product are not recognised at first glance: these include maintenance and installation costs, the operation costs, the training costs for staff and costs for any adjustments. During the production process, aspects such as the target speed, the service life and availability or individual key figures such as OEE play a key role. Furthermore, consumables such as labels must be taken into account; the more precisely these are, for example, linked to labelling and printing systems, the greater their impact is on development of the LCC value.

Regarding life cycle costing, the topic of software is also a matter of major importance as, for example, updates or preventative maintenance are recurring cost factors that ensure the required security and trouble-free function.

Quality is the most cost-effective feature

Individual, high-quality plants or components often have a higher acquisition price, but this is clearly counterbalanced when considering costs over the years. Calculating life cycle costs means products can be compared regarding cost-effectiveness. What becomes clear: quality is worth it. This does not just mean the highest possible availability of machinery, but also within the context of sustainability. The longer a plant reliably functions and can be retrofitted when required, the better the outcome in terms of saving resources. Investigations show that more environmentally friendly products are the result in many cases, even when procurement costs are higher compared to the cheapest version.

Bizerba works on this principle: life cycle costs of Bizerba products are lower on average compared to their competitors. Ultimately, quality, cost-effectiveness and the availability of a product over its entire service life are of the utmost importance for our customers.

Services such as the Bizerba Life Cycle Contract ensure this at every single point of a Bizerba product's service life.

Life cycle contract

Integrated service, applicable to all Bizerba technologies: usage of Bizerba hardware, software and services

Payment terms

monthly, quarterly or annual all-round package

Service

- Delivery and installation of new machinery

- Integration into the existing process landscape

- Repair service

- Preventative maintenance within the individual cycle • Replacement of wear parts as part of preventative maintenance

- Replacement of recommended spare parts as part of preventative maintenance

- Deinstallation of the unit after the contract period has elapsed

Your benefits

+ Transparent life cycle costs (LCC) that can be planned + Increased overall efficiency due to efficient processes