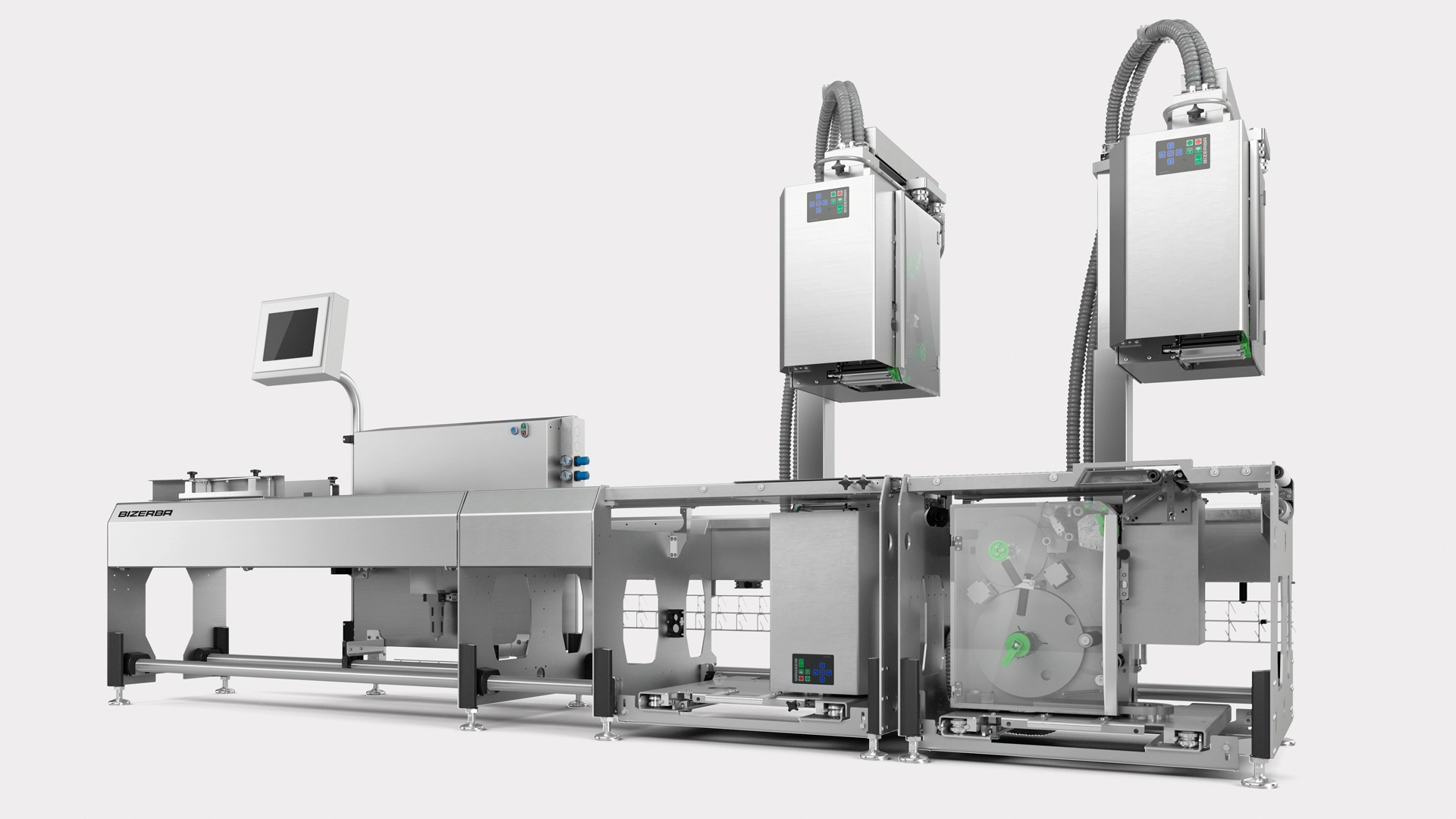

Intelligent Weigh Price goods labelling system GLM-Ievo 70

Intelligent Weigh Price goods labelling system from Bizerba. Unique in it's class and recognised as the worlds leading experts in weigh price labelling systems for the food industry. High Speed High IP protection with intuitive BRAIN software. Easy to operate and maintain incorporating the Bizerba quick belt change system that does not require tools.

The flexible system will easily incorporate into existing production lines seamlessly. Additionally the system will talk to existing software packages with our _Connect BRAIN software module. The Intelligent Weigh Price goods labelling system weighs, labels rejects inferior weights automatically. Depending on the speed requirements and the lines the Weigh Price Goods Labelling System can achieve up wards of 170 packages per minute.

High-tech meeting the highest demands. More customer benefits for future requirements.

The intelligent labelling line GLM-Ievo designed for automatic weighing and labelling of prepackaged goods comes in different versions. Due to its modular design it can be optimally configured for products and performance requirements in the food area.

Thanks to the modular system there are no limits for today's and future requirements in the industrial food area. Besides its flexibility this labelling system stands out in terms of robustness and an easy-to-clean design. With intelligent visual quality control (optional) and automated activation of process data via function "Plug-In®-Label" operation is easier thereby reducing errors during the packaging process.Further more you may want to consider extra protection for your weighed products with the Bizerba inspection systems. We manufacture X-Ray, Metal Detectors and vision inspection systems. Checking pack seal integrity and label positions from above and below.

For more information on the Bizerba range of Intelligent Weigh Price goods labelling system lines or alternative industrial products and services then why not contact us today. We offer free site surveys and consultation visits no obligation quotes. Bizerba offers a solution portfolio allowing you to future proof your production lines.

Highlights

Product images and technical information may differ and may not be available in your country.

Areas of Use

Details & Options

Downloads

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again