"Market for smart load cell systems has plenty of potential"

We supply load cell technology to our internal and external customers. Every day, I work with real specialists so that we can meet requirements to a tee. We use different technologies, depending on the demand.

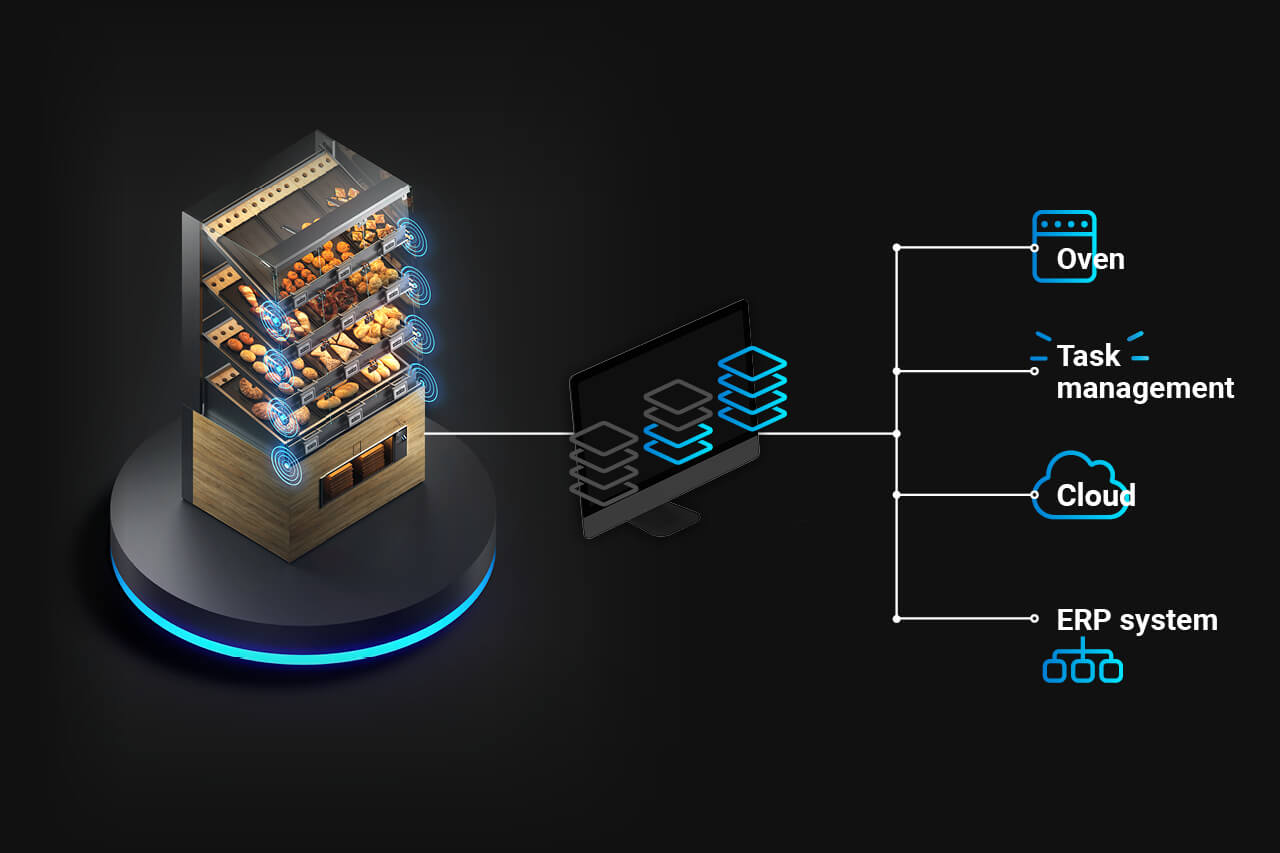

Smart systems, such as weighing rack systems, represent a tremendous future market that has not really been tapped yet. The potential applications for our load cells are diverse. The sooner we and our partners are able to introduce our production-ready systems, the greater our market penetration will be. Given all of the issues that we are focusing on, the challenge will be to select those points and processes that will allow us to quickly achieve the best possible results. We can then further reduce manufacturing costs and increase delivery speed, to the benefit of our customers.

For instance, the strain gauge technology that we use primarily for our best-selling retail products and which, by the way, we also develop and manufacture our own strain gauges. For dynamic weighing, we utilize EMFR, so, electromagnetic force compensation. Another weight measurement method we apply is the vibrating string. My team and I are challenged by wide variety of tasks - keywords: load cell mechanics, analog-digital converters (ADCs), filter technologies and software programming of the ADCs. And finally, an in-house team is responsible for putting the load cells through the paces.

We designed the current WS-MiniSlim series product based on a trade show prototype. The reaction speed was possible thanks to our interdisciplinary, agilely working "Load Cell Basic Technology" team. With this team, we are in a position to implement projects extremely quickly. This way, we support our partners in efforts to serve the sudden demand for intelligent rack systems in a timely manner. The project also gave us as a company a boost of innovation, because the new weighing system does not have the calibration that would otherwise be required in the temperature chambers, thanks to the momentum-free force transmission. Corner calibration is not required either. This significantly reduces manufacturing costs. Because the WS-MiniSlim offers even more potential, we are already planning a facelift with an even slimmer ADC and more simplified assembly.

Like I said, the market for smart systems has barely been tapped so far, so we are focusing on this area in particular. The potential applications for our load cell technologies range from baked goods racks in supermarkets to industrial applications to containers from which skilled trades people can purchase tools and materials 24/7. In this segment, one key competitive factor is the ability to also quickly develop custom solutions. We are in an excellent position to do this, most particularly given our interdisciplinary development team.