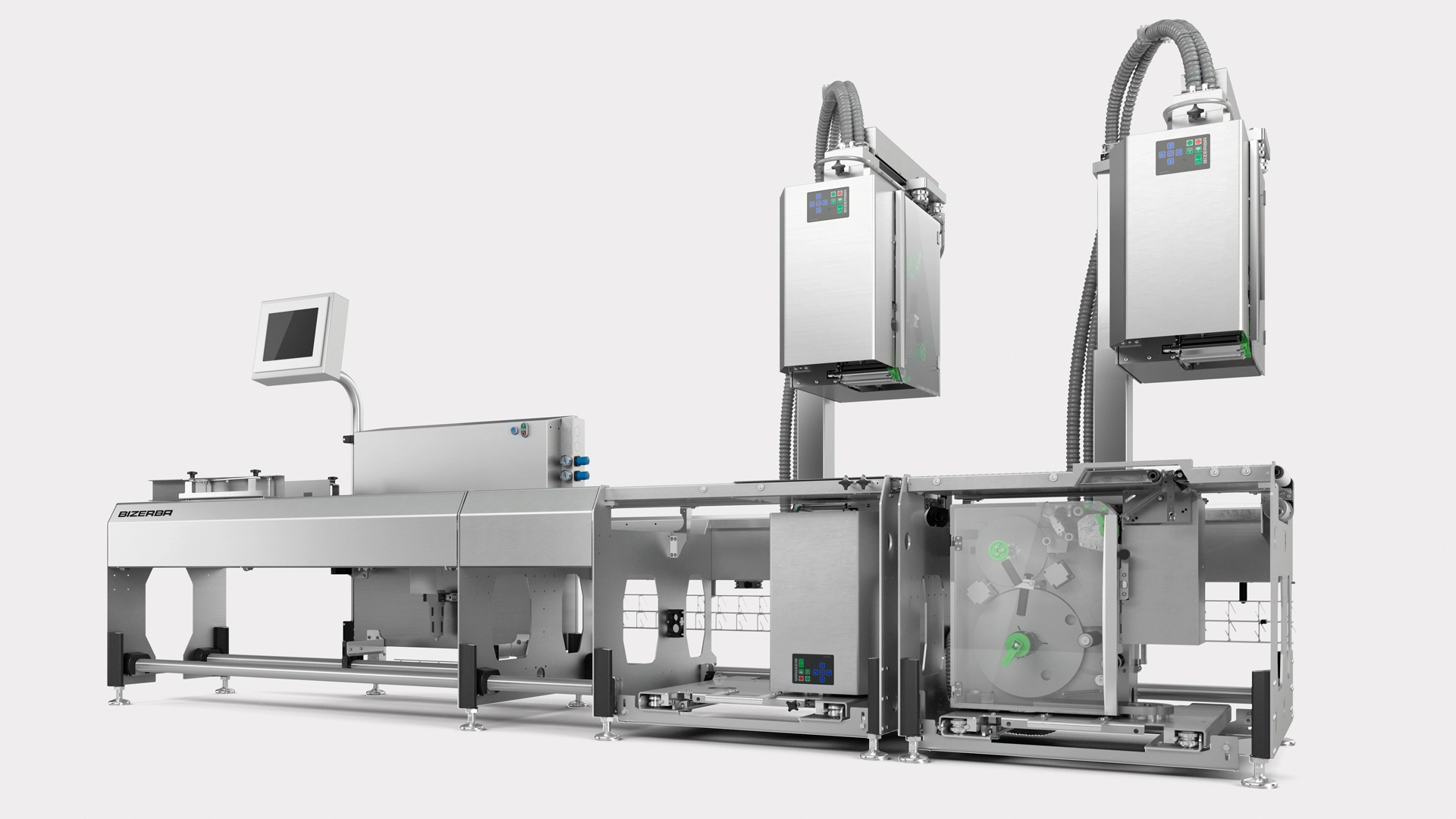

Automatic Weigh Price Label Systems GLM-Ievo 150

The Automatic Weigh Price Label Systems from Bizerba. Introducing the GLM-Ievo 150 capable of weighing and labelling up to 150 packages per minute. Designed for automatic weighing and labelling of pre-packaged goods comes in different versions from the entry level intelligent weigh price goods labelling system GLM-Ievo 70 (70 packages per minute) to the GLM-Ievo 170 weigh price goods labelling system (170 packages per minute) Higher package rates are available upon request.Due to its modular design, it can be optimally configured for products and performance requirements in the industrial food production area. With the Industrial Software makes this system an even more attractive addition to your production plant.

The intuitive software enables you to connect the Automatic Weigh Price Label Systems to existing third party hardware and software. Allowing you to centrally control work flows and production reports in real time.In addition to the standard weigh price labeller we also supply checkweighers for packaged and unpack aged goods including high IP 69 protection Hygienic checkweighers. As well as complete UK coverage for service maintenance and support, we have complete portfolio of industrial equipment that can support your current production plant to include Vision inspection systems, X-Ray food Systems and Metal detectors. Each unit is modular and will integrate seamlessly with any existing hardware you may already have in place.An additional feature built into to all our Weigh Price Labelling Systems is the unique Plug-In® Label system. When a label needs replacing the system reads a unique bar code on the back of each label, if the incorrect roll is inserted the machine will not run. Reducing any errors in the packaging process ensuring the correct label is used every time.For more information on our series of Automatic Weigh Price Label Systems, Checkweighers or Industrial inspection systems then why not contact us today. We offer free consultation visits and site surveys backed by no obligation quotes.

Highlights

Product images and technical information may differ and may not be available in your country.

Areas of Use

Details & Options

Downloads

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again