What is a print and apply labeling system?

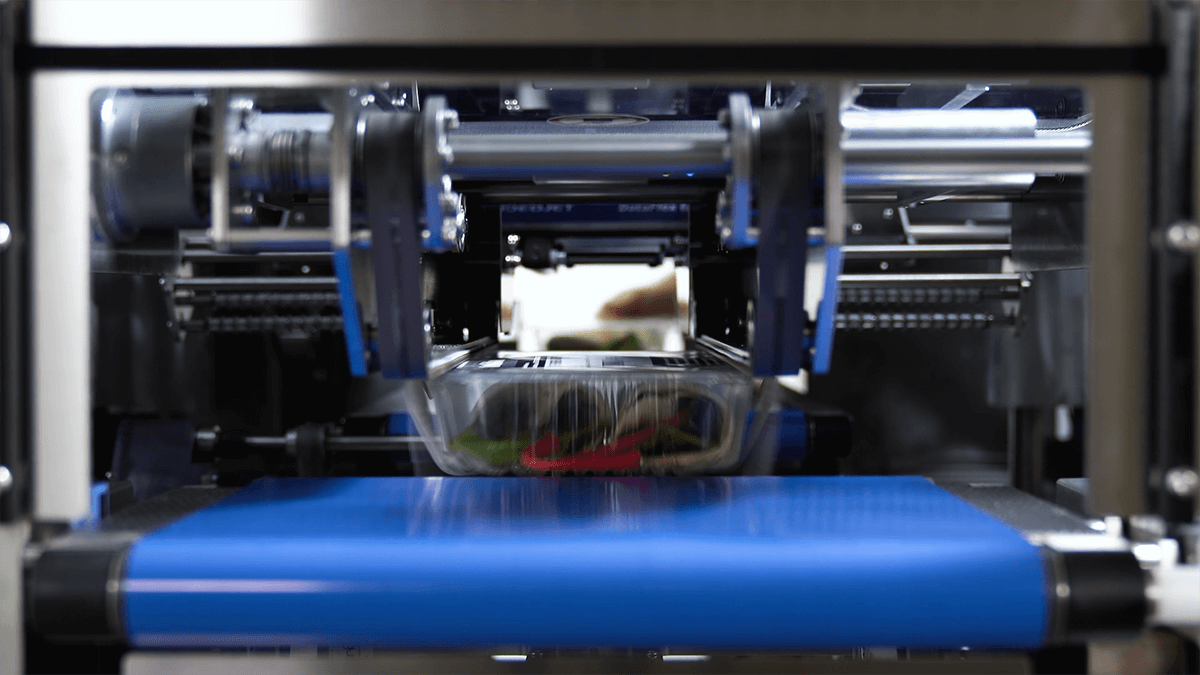

A print and apply labeling system is a tool that combines a high-quality printer with an applicator to automatically print and attach labels to products or packaging. This system is widely used in industries like food production, pharmaceuticals, and logistics, where clear and accurate labeling is a must. By printing and applying labels in one step, this system reduces manual work and ensures every label is correctly placed and easy to read.

Key benefits of print and apply labeling systems

Increased efficiency

With automation, you can label products faster and with fewer mistakes. A printer applicator speeds up your production line, allowing you to manage higher production volumes with ease. This is perfect for industries with tight deadlines and high demand.

High-quality labeling

A print and apply label applicator produces clear, high-quality labels every time. Using advanced printing technology, these labels are durable enough to handle shipping and handling without losing readability. This ensures your products arrive with labels that meet both regulatory requirements and your brand's high standards.

Flexible labeling options

Modern labeling applicators offer a wide range of labeling options. Whether you need to apply top labels, c-wrap labels or full-wrap labels, these systems can be customized to meet your production needs. Their flexibility makes them ideal for businesses handling different product types or needing to switch between labeling formats quickly.

Cost savings

Automating your labeling process can save you money in the long run. With fewer manual tasks, you reduce labor costs and minimize mistakes that can lead to wasted materials or product recalls. These machines are also designed to be user-friendly, which means your team can start using them with minimal training, reducing downtime.

Choosing the right labeling machine for your business

When choosing a print and apply labeling system, it’s important to think about your specific production needs. Consider the following:

- Product size and speed: Your labeling machine should handle different product sizes and keep up with the pace of your production line.

- Easy to use: A good system should be user-friendly, with intuitive controls and easy-to-replace parts. This will reduce downtime and ensure your production line runs smoothly.

- Integration: Look for a machine that integrates well with your existing equipment. Seamless integration means better efficiency and less disruption to your current setup.

Why industrial labeling is important for growth

Labeling is more than just a necessary step—it’s crucial for your brand and compliance. Having a reliable label printer ensures that your labels are clear and durable, which reduces errors during shipping or inventory management. In industries like food production, where accurate labeling is required by law, an automated system is key.

By investing in a print and apply labeling system, your business benefits from the flexibility to update labels as needed. This is especially important if your products change frequently or if regulations require updates to your labels. With automation, you can easily adjust labels to meet new requirements without slowing down your production.

Boost your production line with modern labeling technology

A print and apply labeling system not only makes your production line faster but also improves the quality of your labels. By using advanced printer applicators, your business can manage high volumes while ensuring each product is labeled with precision. This reduces labeling mistakes, lowers waste, and leads to happier customers.

These systems are ideal for businesses looking to optimize their production process. Whether you’re labeling large packages or applying smaller, detailed labels, a high-quality print and apply label applicator will streamline your operations. As your business grows, having a reliable and scalable labeling solution in place will help you keep up with increasing demands while maintaining high standards.