Holistic concepts for the hazardous area

Why do the load cells of the applied load receptors have to be certified accordingly? If a certified weighing terminal is also placed within the hazardous area, many time-consuming procedures are eliminated.

Why do the load cells of the applied load receptors have to be certified accordingly? If a certified weighing terminal is also placed within the hazardous area, many time-consuming procedures are eliminated.

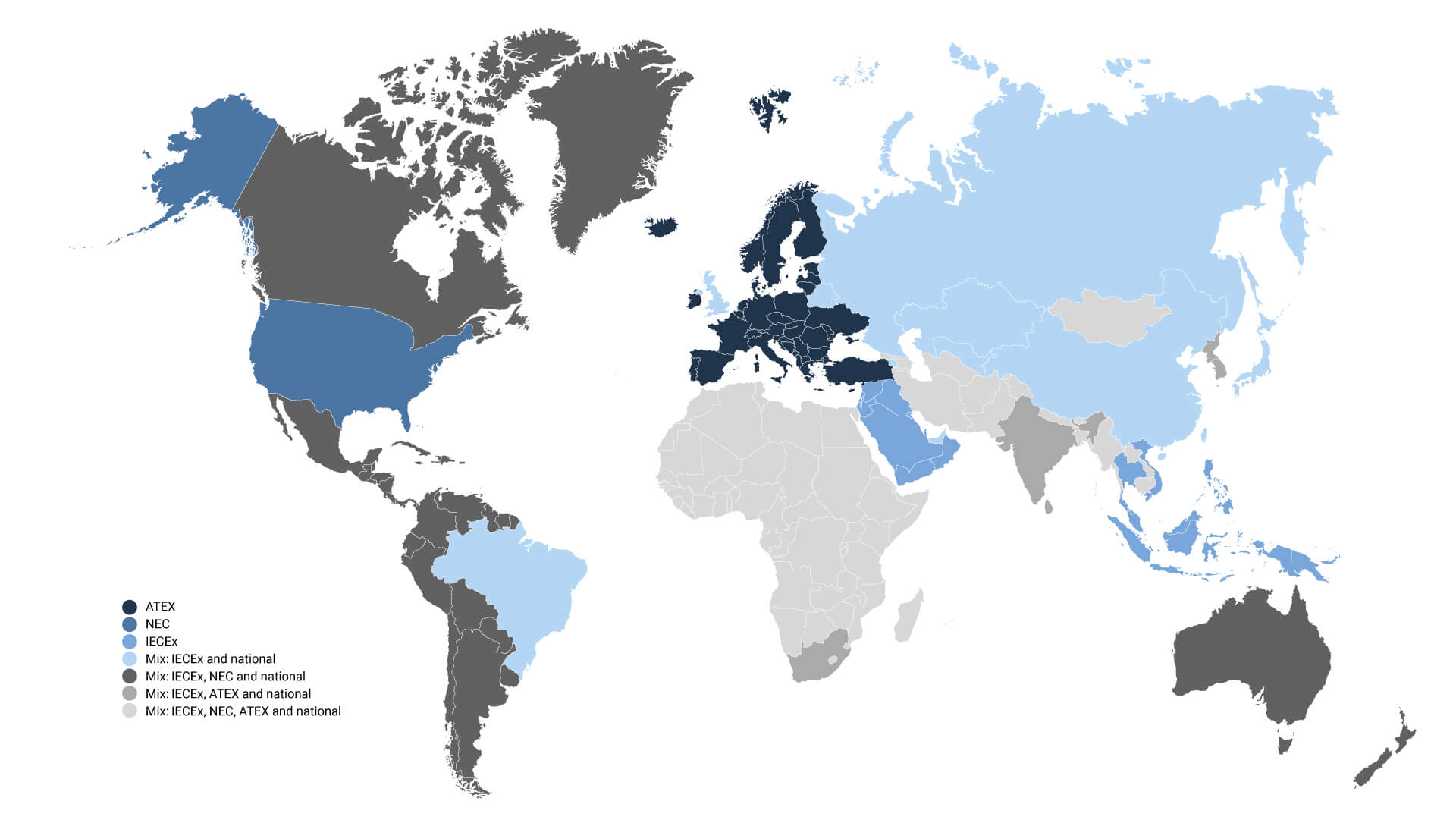

When planning, the hazardous locations must first be determined, as different requirements apply depending on the explosion hazard. Zones are classified according to the frequency or probability of the occurrence of explosive atmospheres. Internationally, there are different categorizations of hazardous locations.

A solution with open software architecture and a sufficient variety of interfaces is always ideal. This allows weighing solutions to be seamlessly integrated into the existing IT system so that networked processes can be mapped without interruption, even in hazardous areas.

Thanks to suitably configured software and individual programming of the soft PLC using Codesys, Bizerba weighing solutions enable maximum flexibility in hazardous areas. They ensure seamless data transfers to higher-level systems and PCs.

Bizerba weighing terminals for hazardous areas have either integrated power supply units or external rechargeable batteries. They have a wide range of interfaces, many of which are intrinsically safe. The load receptors for hazardous areas are available in weighing ranges from 3 to 30,000 kg. Their robust designs with corrosion-free load plates reliably withstand even extreme environmental conditions. Mobile explosion-proof solutions for use in changing locations can also be easily implemented with Bizerba.

Ensure that you comply with local regulations for international rollouts. Bizerba is present in 120 countries with 4,500 employees worldwide. Our experts are very familiar with the regional requirements. In addition to ATEX certificates, we also have IECEx certificates and can therefore provide you with competent support in planning, implementing, certifying and operating internationally compliant weighing solutions in hazardous areas. Another advantage of our global network: In the event of a service call, response times are short, whether on-site or via remote support.

Whether for the chemical industry, pharmaceutical manufacturers or food producers; from incoming or outgoing goods to filling, dosing or mixing: With us, you will find explosion-proof weighing solutions that meet your requirements to the letter, integrate seamlessly into your production and reliably comply with all local laws and regulations.