Optimise your production while labeling

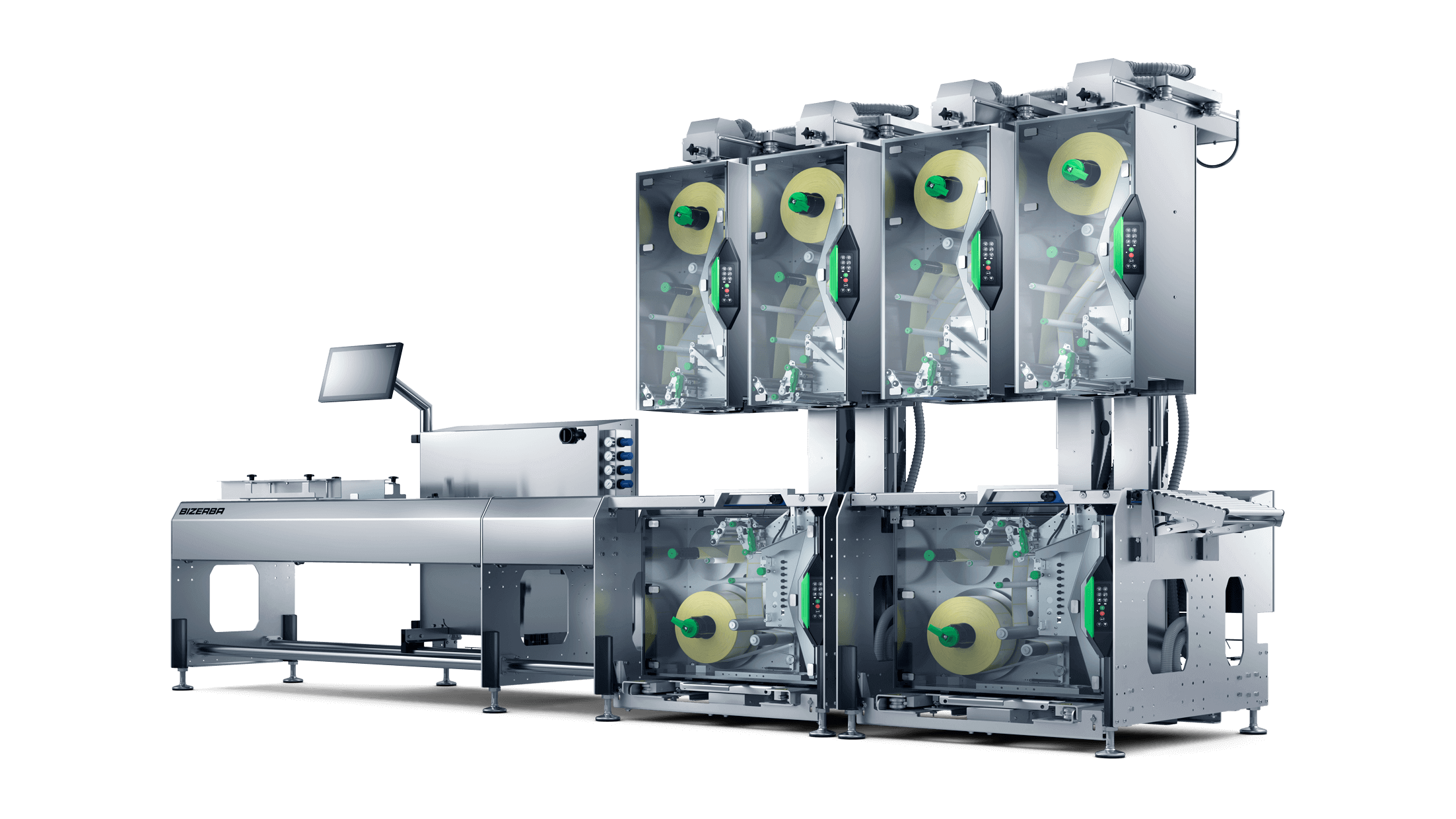

More powerful than ever – the new GLM-I series

Higher efficiency – even for complex, increased requirements

Designed to save up to 30% space savings

Gain new opportunities with the one-of-a-kind compact GLM-I. With its new, slim design, the labelling unit has significantly reduced its footprint compared to the GLM-Ievo series. Use the space you've gained for

- Space-saving, streamlined installation on your production line

- Utilizing up to six labelling units in the GLM-I system

- Consider integrating inspection systems for a reliable packaging & production inspection. Without compromising on space.

Performance up, downtime down

How can we reduce your downtime? That was one of our goals when developing the new GLM-I generation. Leveraging high-end features for faster processes:

- Fully automatic setup for optimized article call-up, new: now for top & bottom labelers.

- Individually controllable & optimally coordinated labelling units & label dispensers

- Seamless product and label roll changeovers during ongoing operation

- Direct access to the labelling unit, always accessable to the operator, no matter the conveying direction

With its modular design, be ready for tomorrow

Invest in a weigh price labelling system that enables you to satisfy new requirements in the long-term. Design the exact solution you need from a wide range of models and options:

- Precisely customized starter solution, e.g. number of labellers top/bottom, applicators, etc.

- Can also be customized through the Customer Solution Center

- Number of labelling units can be upgraded at any time on request: up to 10 labelling units + label dispensers in one line

- System can be expanded as required, e.g. with Bizerba metal detectors & vision inspection systems

Intuitively always on top of production

Using the new GLM-I user interface, experience just how easily the advanced system can be operated. Follow the current status of all systems and integrated inspections systems on the newly designed dashboard. Quickly adjust the label position with a mere touch. Detect the label fill-levels at a glance. Ideal for efficient handling and optimum product quality.

Our various weigh price labeling systems of the GLM-I series

Ready for 4.0 via BRAIN2 industrial software

3 features that strengthen your competitive advantage

What retail means today: You have to respond to the market needs quickly and flexibly. Produce an increasingly broad range of products. And whether your fresh food product finds its way into the shopping cart will also be decided by the next trend. Your GLM-I weigh price labelling system makes you ready for almost any challenge. With one line only. Today and tomorrow. A good argument for your business case.

Clear trend: transparent packaging

Transparent hard trays in the fresh produce rack are a current packaging trend. Consumers are immediately drawn to this appealing design: they see the color and shape of the product and have a clear impression of the quality of the goods. Two important factors that result in a purchasing decision.

Transparent labels reinforce this powerful selling design. Their use is also achievable with the GLM-I series thanks to the ultrasound sensor. A real added value that put you a step ahead of the competition.

Strong demand: small batch sizes

More and more retailers are ordering smaller, customized quantities. Meet this demand leanly and profitable. Your GLM-I model provides fluent and flexible workflows that increase your production line utilization. Produce small batch sizes with zero downtime: Automatically adjust the price labeling system to the next batch size & change labels seamlessly on up to six integrated labeling units on all standard models.

High in demand: a broad range of products

Consumers have a tremendous hunger for variety –especially in the fresh produce sector. The variety of refrigerated products in retail is on the rise. Currently, plus cooling accounts for 50% of the cooling area*. With this rising tendency. With the GLM-I series you get two features to serve this trend efficiently with just one line in running operation:

- A large number of labellers that you can load with a variety of label rolls, enabling even chaotic production on the fly, for example

- Automatic product settings for quick product and label changes.

*Source: EHI Study "Refrigeration Technology in Food Retail 2021"

Satisfying food standards efficiently

Expand the unique performance of your GLM-I price labelling system. For example with an AI-based vision inspection, which satisfies international food standards such as IFS. The LabelSecure vision inspection system does just that. Objectively, quickly and reliably. Even at high throughput levels.

With the inline solution, you can check whether the label contains the correct information – matching the product. Benefit from seamless traceability with automatically generated reports. Another advantage: LabelSecure provides process analysis and control in real time. Your key to saving resources.

All From One Source

Let’s Count

Any Questions?

We developed the GLM-I series with your needs in mind, i.e.

> production speed/ppm

> fresh food packaging

> applicators, and

> amount of information you want to print on your label.

Select your model. We would be happy to discuss its relevant performance.

All options

GLM-I 70/100/150/170

GLM-I C-Wrap, available for delivery as of 2024

GLM-I CleanCut, available for delivery as of 2024